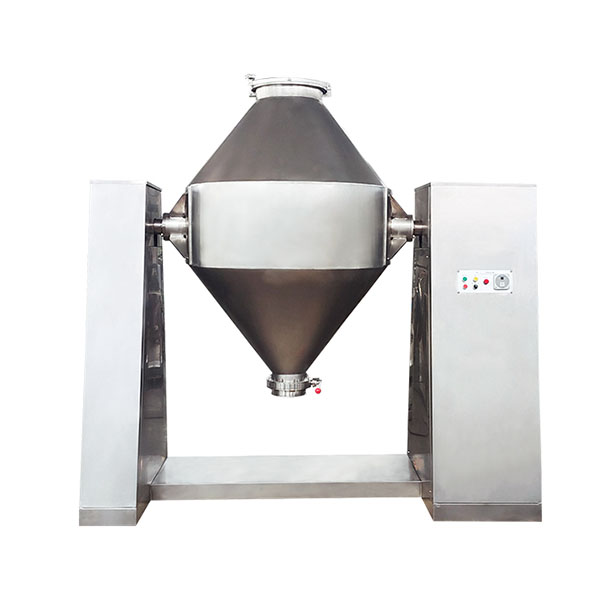

Conical Screw Mixer

Product DescriptionThe conical screw (Nauta) mixer is a convective gentle mixer with high mixing efficiency. It is a highly efficient vertical powder mixer with low energy consumption for batch mixing...

Product Description

The conical screw (Nauta) mixer is a convective gentle mixer with high mixing efficiency. It is a highly efficient vertical powder mixer with low energy consumption for batch mixing of powder and granules of various particle sizes.

Working Principle

The spiral moves the materials upward along the central shaft, where the materials drop by its gravity in the center. At the same time, the screw arm revolves around the central shaft to keep the materials rotating and dispersing in the mixer. The whole mixing forms a three-dimensional action, where raw materials are sheared and diffused repeatedly in the vessel.

Features and Benefits

Gentle blending action is ideal for friable materials.

Low heat generation, suitable for heat-sensitive products.

Fully discharged without any residual in the conical vessel.

High efficiency and excellent homogeneity with a short mixing cycle time.

Reliable heavy-duty gear driving device with strong-rated torque.

Low energy consumption compared with other types of mixers.

Typical Application

mixing and homogenizing of granular, dust, and paste-like materials.

Salts, Lactose, Gelatin, Starch, Fiber, Soy Protein, Spices, Cellulose, Seasonings, Nutraceutical, Proteins, Vitamins, Catalysts, Kaolin, Metallic Compounds, Silica, Calcium Carbonate, Pigments, Zinc Oxide, Detergents, Dyestuff, Resin, etc.

Technical Data

Model | Volume (L) | Capacity (kg) | power (kw) | Speed (r/min) | Dimension(mm) | Weight(kg) |

DSH-0.3 | 300 | 180 | 2.2/0.55 | 143/2 | Φ990×1850 | 490 |

DSH-0.5 | 500 | 300 | 3/0.55 | 143/2 | Φ1130×2100 | 660 |

DSH-1 | 1000 | 600 | 4/1.1 | 57/2 | Φ1490×2600 | 1200 |

DSH-1.5 | 1500 | 900 | 5.5/1.1 | 57/2 | Φ1660×2900 | 1350 |

DSH-2 | 2000 | 1200 | 5.5/1.5 | 57/2 | Φ1815×3100 | 1500 |

DSH-2.5 | 2500 | 1500 | 7.5/1.5 | 57/2 | Φ1920×3170 | 1800 |

DSH-3 | 3000 | 1800 | 7.5/1.5 | 57/2 | Φ2055×3280 | 2300 |

DSH-4 | 4000 | 2400 | 11/2.2 | 57/1.8 | Φ2300×3830 | 2500 |

DSH-5 | 5000 | 3000 | 15/2.2 | 57/1.8 | Φ2450×4100 | 2800 |

DSH-6 | 6000 | 3600 | 15/2.2 | 57/1.8 | Φ2630×4300 | 3000 |

DSH-8 | 8000 | 4800 | 18.5/4 | 45/1.2 | Φ2820×4700 | 4500 |

DSH-10 | 10000 | 6000 | 22/4 | 45/1.2 | Φ3000×5000 | 5500 |

DSH-15 | 15000 | 9000 | 30/4 | 41/0.8 | Φ3450×5800 | 6800 |

Note:

The above-listed capacity is calculated as per powder with a bulk density of 0.6 g/cm3 as a medium.

The model selection should depend on comprehensive factors such as material properties, bulk density etc.