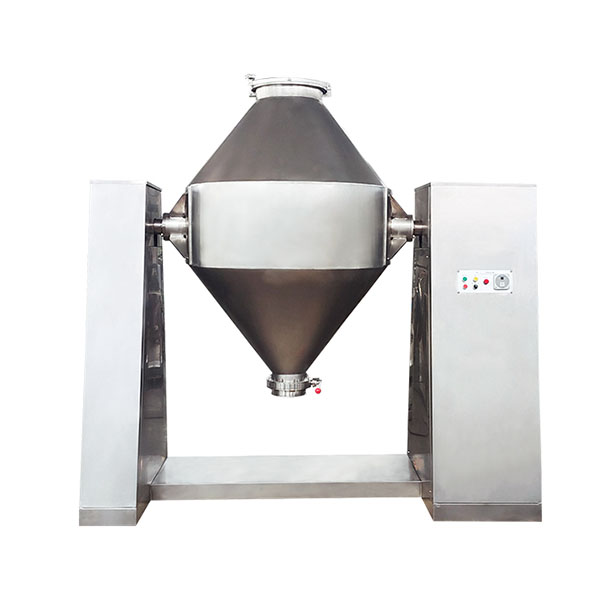

Double Cone Mixer

Product DescriptionThe Double Cone mixer is ideal for mixing fragile sensitive products. Low speed rotating drum makes the product slide gently on its inner walls, performing a non-forced mixing effec...

Product Description

The Double Cone mixer is ideal for mixing fragile sensitive products. Low speed rotating drum makes the product slide gently on its inner walls, performing a non-forced mixing effect.

Working Principle

The materials are introduced into the double cone mixer through the loading port. Through the rotation of the vessel, the material is repeatedly polymerized and separated by its gravity and centrifugal force to achieve uniform mixing.

Features and Benefits

Gentle blending action is ideal for friable materials.

Low heat generation, suitable for heat-sensitive products.

Double cone arrangement achieves efficient rolling and cross-mixing.

Sanitary butterfly discharge valve for quick disassembly.

Fully discharging with Cross Contamination Free Via Gravity.

Low Energy Consumption and Minimum Maintenance.

Typical Application

Free-flowing dry powder, granules, dense and abrasive material.

Metal powder, ceramic powder, lithium battery, pharmaceutical granules, animal feed, Healthcare, flour, seeds, starch, coffee beans, ground coffee, cocoa, chocolate granules detergent granules, soap flakes, etc.

Technical Data

Model | Volume (L) | Capacity (kg) | power (kw) | Speed (r/min) | Dimension(mm) | Weight(kg) |

SZH-0.1 | 100 | 50 | 1.1 | 15 | 1400X550X1500 | 200 |

SZH-0.2 | 200 | 100 | 1.5 | 15 | 1500X800X1650 | 300 |

SZH-0.3 | 300 | 150 | 2.2 | 15 | 1700X800X1850 | 500 |

SZH-0.5 | 500 | 250 | 3 | 15 | 2000X1100X1950 | 800 |

SZH-1 | 1000 | 500 | 5.5 | 12 | 2400X1200X2200 | 1200 |

SZH-1.5 | 1500 | 750 | 5.5 | 12 | 2400X1200X2200 | 1500 |

SZH-2 | 2000 | 1000 | 7.5 | 12 | 2400X1200X2200 | 1800 |

Note:

The above-listed capacity is calculated as per powder with a bulk density of 0.6 g/cm3 as a medium.

The model selection should depend on comprehensive factors such as material properties, bulk density etc.