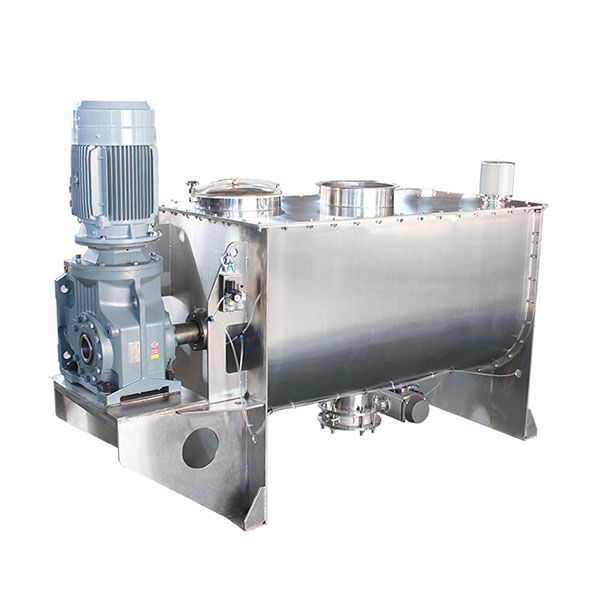

Ribbon Paddle Mixer

Product DescriptionThe ribbon paddle mixer is versatile blending equipment with high efficiency, uniformity, and low crushing. Its double ribbon agitator can make the materials well mixed in a short t...

Product Description

The ribbon paddle mixer is versatile blending equipment with high efficiency, uniformity, and low crushing. Its double ribbon agitator can make the materials well mixed in a short time, widely applied for mixing dry powders, granules, and viscous pastes homogeneously.

Working Principle

The inner ribbons move materials toward the ends of the ribbon blender whereas the outside ribbons move material back toward the center of the ribbon blender. The ribbons move materials both radially and laterally to ensure thorough blends in short cycle times. the materials form the axial reciprocating motion in the mixing chamber.

Features and Benefits

High efficiency and excellent homogeneity with a short mixing cycle time

Gentle blending action is ideal for friable materials.

Simple structure, easy to dismantle, and maintenance.

Various process connections, surface finishes and shaft sealings

Sanitary design improves discharge and makes cleaning easier.

Various types of agitator arrangements can be tailored to fit different materials.

Typical Application

Blending free-flowing powders, pellets, flakes, granules, pastes, slurries, and dough.

Instant Food, Milk Powder, Essence, Enzymes, Flavoring Agents, Seasoning, Sugar,

Mineral Substance, Flour, Bakery, Food Additives, Vitamin compounds, Cosmetics

Technical Data

Model | Volume (L) | Capacity (kg) | power (kw) | Speed (r/min) | Dimension(mm) | Weight(kg) |

WLH-0.3 | 300 | 180 | 4 | 63 | 1900×860×1000 | 750 |

WLH-0.5 | 500 | 300 | 5.5 | 63 | 2000×820×1300 | 900 |

WLH-1 | 1000 | 600 | 11 | 41 | 2500×1000×1600 | 1600 |

WLH-1.5 | 1500 | 900 | 15 | 33 | 2800×1100×1520 | 1700 |

WLH-2 | 2000 | 1200 | 18.5 | 33 | 3000×1200×1800 | 2000 |

WLH-2.5 | 2500 | 1500 | 18.5 | 33 | 3500×1200×1900 | 2300 |

WLH-3 | 3000 | 1800 | 22 | 29 | 3500×1360×2000 | 2700 |

WLH-4 | 4000 | 2400 | 22 | 29 | 3900×1600×2200 | 3900 |

WLH-5 | 5000 | 3000 | 30 | 26 | 4300×1680×2200 | 4800 |

WLH-6 | 6000 | 3600 | 37 | 26 | 4360×1860×2300 | 5600 |

WLH-8 | 8000 | 4800 | 45 | 19 | 4600×2200×2300 | 6500 |

WLH-10 | 10000 | 6000 | 55 | 19 | 5200×1850×2800 | 8000 |

WLH-15 | 15000 | 9000 | 75 | 17 | 6000×2000×2910 | 9600 |

WLH-20 | 20000 | 12000 | 75 | 17 | 6100×2500×3100 | 12000 |

WLH-25 | 25000 | 15000 | 90 | 17 | 7000×2500×2900 | 15000 |

WLH-30 | 30000 | 18000 | 110 | 17 | 7100×2600×3100 | 16000 |

Note:

The above-listed capacity is calculated as per powder with a bulk density of 0.6 g/cm3 as a medium.

The model selection should depend on comprehensive factors such as material properties, bulk density etc.