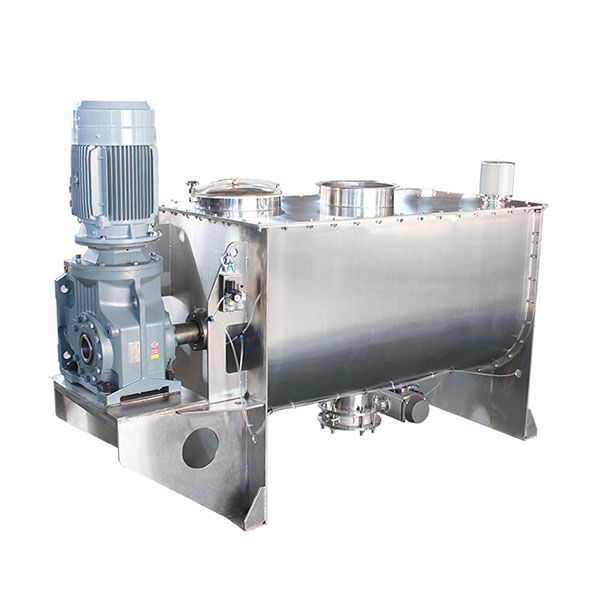

Plough Shear Mixer

Product DescriptionThe plough shear mixer is a high efficiency, uniformity, and intensive mixing equipment. especially for processing high-density granular and powder. high-speed choppers are ideal fo...

Product Description

The plough shear mixer is a high efficiency, uniformity, and intensive mixing equipment. especially for processing high-density granular and powder. high-speed choppers are ideal for breaking up lumps and agglomerates.

Working Principle

The plough disperses materials in an axial direction during high-speed rotation but also drives the materials to flow in circles around the cylinder wall, which efficiently settles the stratification during mixing. At the same time, choppers rotate at high speed to break the agglomeration.

Features and Benefits

High-speed choppers reduce the cycle time of minor ingredients.

Ideal for Breaking Up Lumps and Agglomerates.

High efficiency and excellent homogeneity with a short mixing cycle time.

Liquid can be introduced into the powder by spray nozzles.

Jacketed mixing cylinder for heating and cooling function.

Large access door with safety switches for cleaning purposes.

Typical Application

Mixing of powders, granules, flakes, fibers and pastes

metal powders, minerals, friction material, ceramics, cement, sand, carbon black, fire retardants, talcum powders, glass melts, soldering agents, etc.

Technical Data

Model | Volume (L) | Capacity (kg) | power (kw) | Speed (r/min) | Dimension(mm) | Weight(kg) |

LDH-0.3 | 300 | 180 | 4+1.5*2 | 85/1440 | 1950×1100×940 | 800 |

LDH-0.5 | 500 | 300 | 5.5+1.5*2 | 85/1440 | 2050×1250×1140 | 1000 |

LDH-1 | 1000 | 600 | 11+2.2*3 | 63/1440 | 2600×1450×1310 | 1800 |

LDH-1.5 | 1500 | 900 | 15+3*3 | 63/1440 | 2900×1500×1410 | 1900 |

LDH-2 | 2000 | 1200 | 18.5+3*3 | 63/1440 | 3200×1700×1500 | 2100 |

LDH-3 | 3000 | 1800 | 22+3*3 | 63/1440 | 3500×1800×1690 | 3100 |

LDH-4 | 4000 | 2400 | 22+4*3 | 50/1440 | 3700×1950×1870 | 4300 |

LDH-5 | 5000 | 3000 | 30+4*3 | 50/1440 | 4100×2000×1920 | 5300 |

LDH-6 | 6000 | 3600 | 37+4*3 | 50/1440 | 4250×2150×2060 | 6000 |

LDH-8 | 8000 | 4800 | 45+4*4 | 41/1440 | 5300×2240×2160 | 7300 |

LDH-10 | 10000 | 6000 | 55+4*4 | 33/1440 | 5600×2400×2420 | 8200 |

LDH-15 | 15000 | 9000 | 75+5.5*4 | 29/1440 | 6100×2700×2570 | 11000 |

Note:

The above-listed capacity is calculated as per powder with a bulk density of 0.6 g/cm3 as a medium.

The model selection should depend on comprehensive factors such as material properties, bulk density etc.