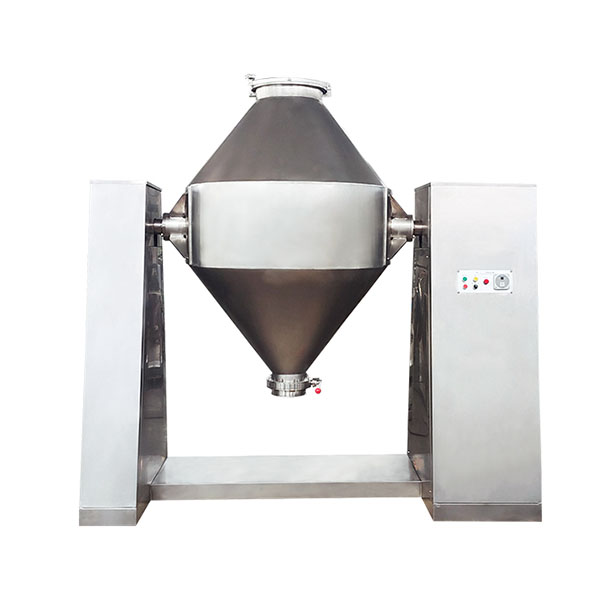

V Shape Mixer

Product DescriptionV-shape blender is mainly used to produce homogeneous solid-solid mixture, especially for fragile materials in small, batch and has high uniformity requirement.Working PrincipleThe...

Product Description

V-shape blender is mainly used to produce homogeneous solid-solid mixture, especially for fragile materials in small, batch and has high uniformity requirement.

Working Principle

The solids are introduced into the mixer through the loading port. With the rotation of the mixing chamber, the powder particles are divided and merged repeatedly in the V-shaped cylinder. The material flows randomly in the drum i.e., repeatedly diffusion motion to achieve a uniform mixing effect.

Features and Benefits

High uniformity for pre-mixing and free-flow materials.

V shape ensures good rolling and cross mixing in shorter mixing times.

Low heat generation, suitable for heat-sensitive products.

Gently blending fragile granules without crumbling.

V-shaped cylinder allows easy access to internal cleaning.

Fully discharging with Cross Contamination Free Via Gravity.

Typical Application

Ideal for pre-mixing and blending free-flow dry powder and granules

pharmaceuticals, fish meal, flour, dextrin, enzymes, coffee, cocoa, milk powder, chocolate, gelatin, crème caramel and dessert powder, baby food, custard powder, starches, pigments, colorants, cosmetics, powdered plastics, etc.

Technical Data

Model | Volume (L) | Capacity (kg) | power (kw) | Speed (r/min) | Dimension(mm) | Weight(kg) |

VH-0.1 | 100 | 40 | 1.1 | 15 | 1600X600X1400 | 200 |

VH-0.2 | 200 | 80 | 1.5 | 15 | 1900X700X1500 | 300 |

VH-0.3 | 300 | 120 | 2.2 | 15 | 2190X700X1700 | 500 |

VH-0.5 | 500 | 200 | 3 | 15 | 2340X800X2200 | 800 |

VH-1 | 1000 | 400 | 5.5 | 12 | 2900X1100X2300 | 1200 |

VH-1.5 | 1500 | 600 | 5.5 | 12 | 3000X1200X2900 | 1500 |

Note:

The above-listed capacity is calculated as per powder with a bulk density of 0.6 g/cm3 as a medium.

The model selection should depend on comprehensive factors such as material properties, bulk density etc.