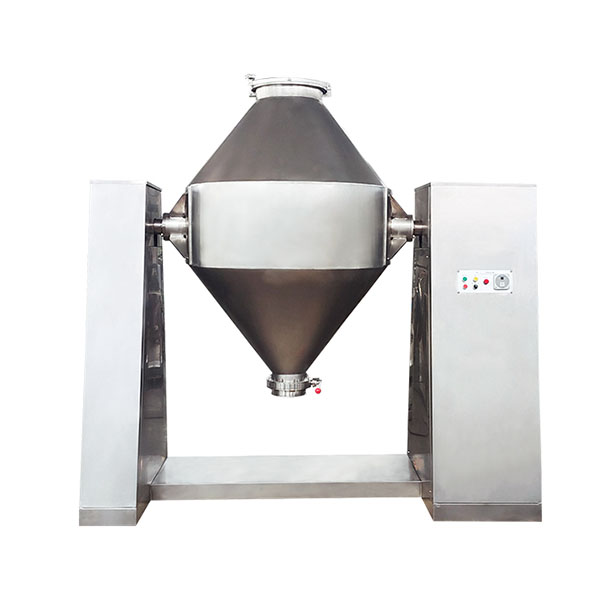

Three Dimension Mixer

Product DescriptionThe three dimensional mixer is used to evenly mix powders and granules in a time-efficient and cost-effective method. The three-direction movement produces a uniform blend of ingred...

Product Description

The three dimensional mixer is used to evenly mix powders and granules in a time-efficient and cost-effective method. The three-direction movement produces a uniform blend of ingredients for a wide range of pharmaceutical drugs & different materials

Working Principle

The mixing barrel makes unique turning, translation, and rolling motions in the three dimensional space, thereby speeding up the flow and diffusion of the materials, while avoiding the specific gravity segregation of the materials due to the action of centrifugal force and ensuring the materials reach an ideal mixing within a short time.

Features and Benefits

High efficiency and excellent homogeneity with a short mixing cycle time.

Gentle blending action is ideal for friable and free-flow materials.

Closed container ensures that the powder blending is dust-free.

Large access port allows easy access to internal cleaning.

The loading/discharge can be carried out with a vacuum feeder.

Guard rail to prevent the operator from accessing it when in operation.

Typical Application

Ideal for mixing free-flow dry powder and granules

pharmaceuticals, fish meal, flour, dextrin, enzymes, coffee, cocoa, milk powder, chocolate, gelatin, crème caramel and dessert powder, baby food, custard powder, starches, etc.

Technical Data

Model | Volume (L) | Capacity (kg) | power (kw) | Speed (r/min) | Dimension(mm) | Weight(kg) |

SYH-50 | 50 | 25 | 1.1 | 20 | 900X1250X1200 | 200 |

SYH-100 | 100 | 50 | 1.5 | 15 | 1300X600X1500 | 400 |

SYH-200 | 200 | 100 | 2.2 | 15 | 1400X1700X1750 | 500 |

SYH-400 | 400 | 200 | 4 | 15 | 1800X2100X2200 | 800 |

SYH-600 | 600 | 300 | 5.5 | 10 | 1850X2200X2300 | 1000 |

SYH-800 | 800 | 400 | 7.5 | 10 | 2000 X2300X2550 | 1200 |

SYH-1000 | 1000 | 500 | 11 | 10 | 2100X2500X2640 | 1500 |

Note:

The above-listed capacity is calculated as per powder with a bulk density of 0.6 g/cm3 as a medium.

The model selection should depend on comprehensive factors such as material properties, bulk density etc.